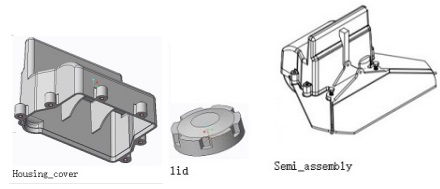

*Parts name: White UV resistent plastic parts (17th Jan., 19)

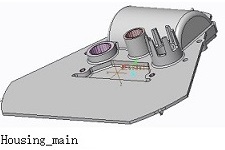

*Application: Lora rain gauge

*In material: PC-1003R (w/ blue base color from pigment making viewpoint)

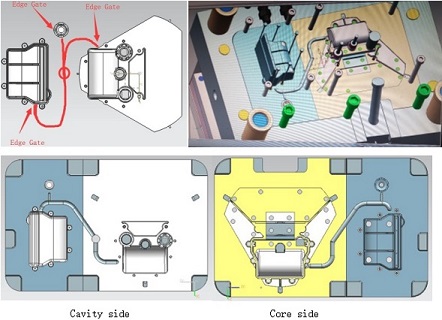

*One tooling: 1x1x1 cavities

Steel material for core and cavity: 718H

*Injection gate structure:Edge sprue

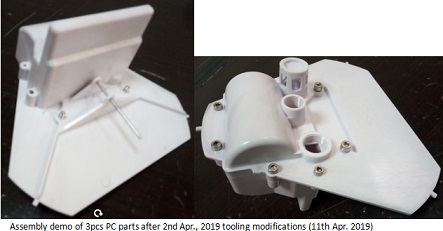

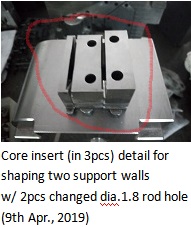

*Dia.2mm holes at top of 2pcs support wall changed to Dia.2.5mm, steel pin in this diameter which form these holes fixed on slide system is durable during repeated moulding process. The 2pcs Dia.2mm holes are changed to Dia.1.8, then they are enlarged by drilling way to Dia.1.97 ~ 1.98, so nominal dia.2mm(actually a bit less) rod can be held tightly in them.

* Housing_cover : 6pcs DIN912 M3 screws

Housing_main : 1pcs Pg7 cable gland with sealing ring

1pcs Pg9 plug with sealing ring

2pcs DIN933 M4 screw

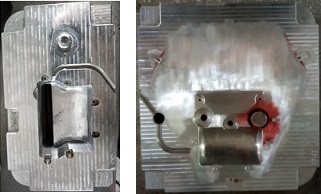

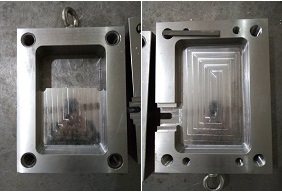

*Parts, injection gate(sprue) and runner layout in tooling:

Tooling design snapshot(23rd Jan., 19)

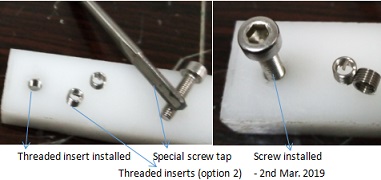

*6pcs M3 thread holes on Housing_cover part, these are to be made by drilling (Option1)

Option 2: Use special installation tool to push threaded insert rotating down lightly into screw hole until the end of it is no more than between 1/4 to 1/2 lap away from workpiece plane. option 2 can significantly improve threaded joint strength and wear resistance; prevent loose threads and slippery teeth

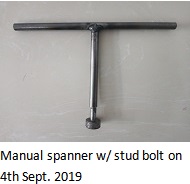

1pc Pg7, 1pc Pg9 and 2pcs M4 thread holes on housing_main part are intended to be formed by stud bolts in molding process

Stud bolts(6pcs for M4 threaded holes, 3pcs for each Pg7 and Pg9 threaded holes) - 9th Mar., 2019

*Fine EDM texture on visible surfaces need to be changed to eroding one because of some inaccessible surface positions to EDM work.(15th Feb., 2019)

*Using edge injection gate for parts: faster melted plastic flow, combined with curved runner, PC parts have better surface looking - no 'ripple' trace.

*Assembly between lid part and housing_main part is tight fit.

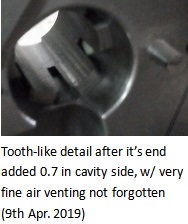

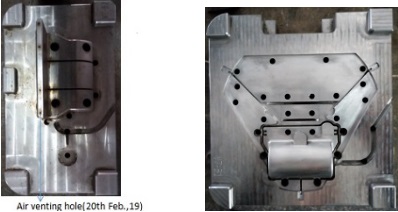

*Air venting holes solve 'air-trapping' trouble and help fully filling plastic around steel wall, risk of steel deformation is reduced to stand up to long moulding cycle time. Core insert in 3pcs works as same function.