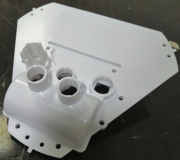

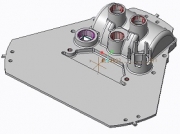

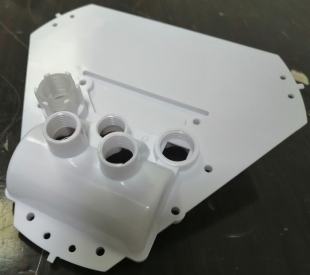

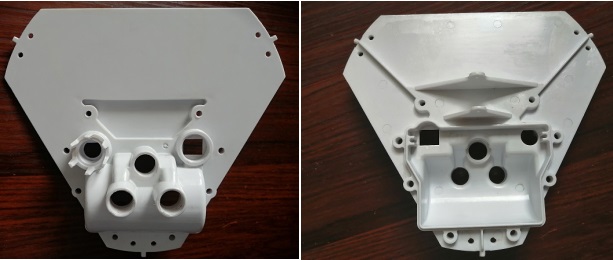

*Part name: Lora_raingauge_housing_main (soil) part

*In white UV stabilized PC

*Cavities: 1x1

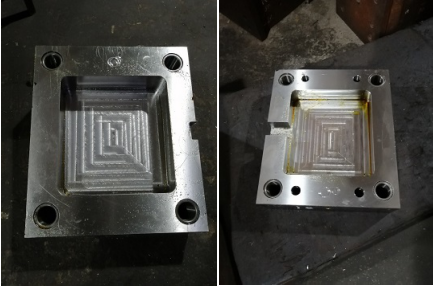

*Mold Cavity & core in material: 718H steel; mold base in material 45C steel

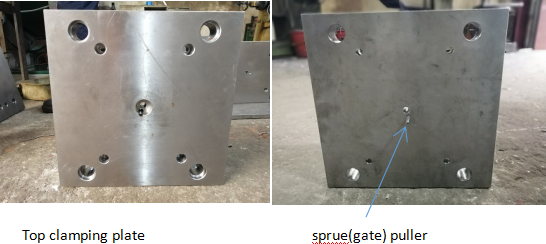

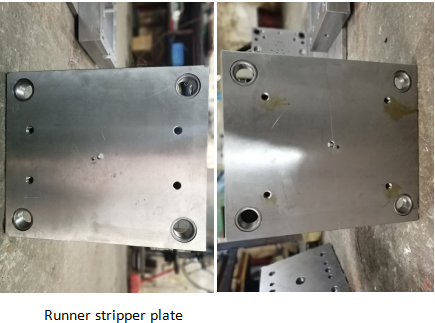

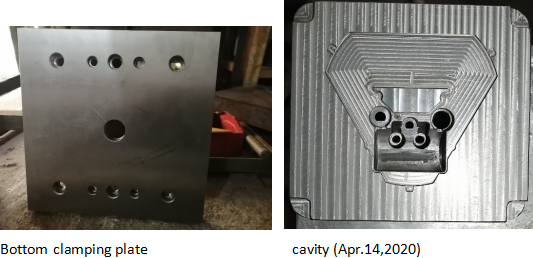

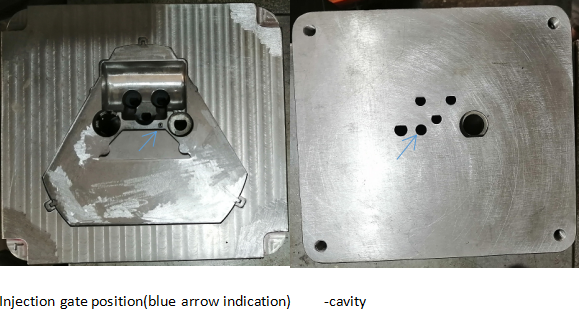

*Pin point injection gate

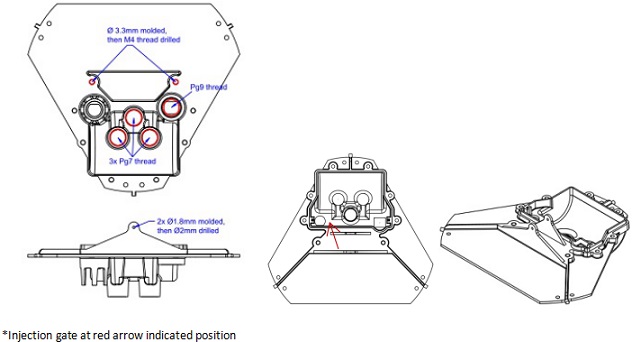

*Plastic injection tooling is built according to shrinkage rate: 5‰

Injection gate at central position, facilitating melted plastic flow evenly to all directions.

Threaded holes are to be formed by stud bolts, they are removed immediatley after part is molded

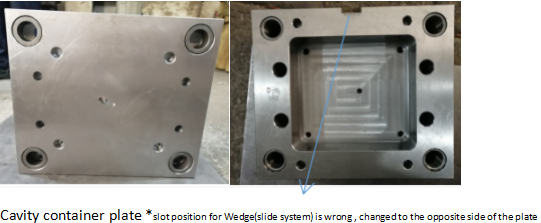

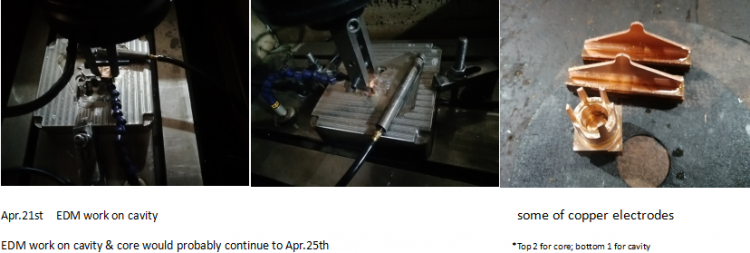

*Mold base machining work is finished on Mar. 31st, cavity & core materials are going through wire cutting processing and should be ready for EDM machining work on Apr. 6th or 7th., copper electrodes would be prepared by CNC milling work at same time period.

Apr.6th, 2020

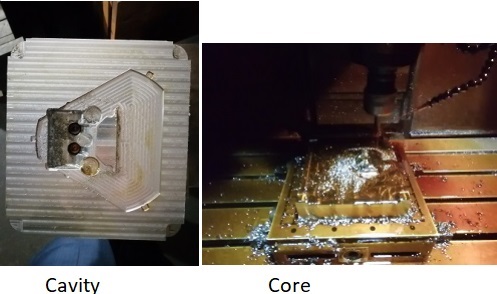

a. Milling work on cavity is finished, wire cutting and EDM work will follow

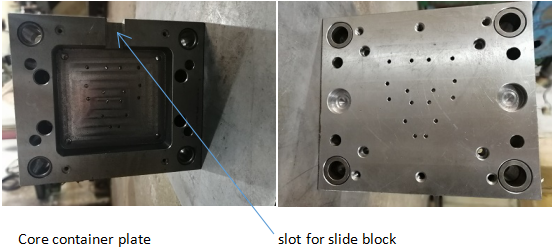

b. Milling work on core is going on, EDM work will follow

c. Stud bolts shaping threaded holes(pg7, pg9 etc.) are being made

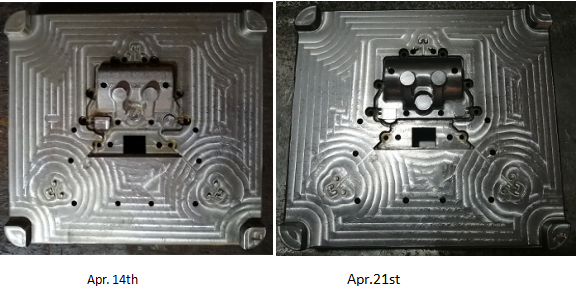

*Apr.14,2020 plastic mold making status:

*core section situation after wire-cutting processing

*Stud bolts for shaping threaded holes(pg7, pg9 etc.) are ready for using.

*In the EDM machining process for the feature  , there was carbon deposition produced. welding work is being done on cavity, followed by EDM wok again, but in shortest time. -Apr. 29th

, there was carbon deposition produced. welding work is being done on cavity, followed by EDM wok again, but in shortest time. -Apr. 29th

*Front/back of core: chamfer at ejector pin hole edge of core back, convenient for put ejector pins into holes

*middle picture: Nominal Dia 2.0 pin is put into the through hole in the core at wrong side, it should be from opposite one. the through hole is made by wire cutting processing. -May 12th, 2020

1st time trial shot parts -May 13th, 2020

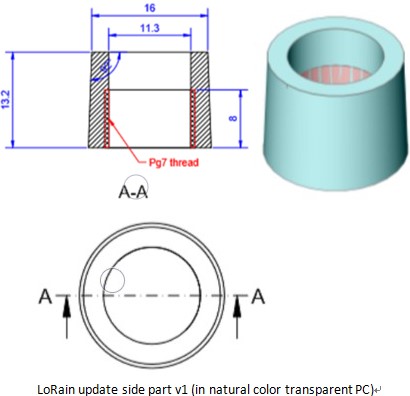

Turn workflow: a. Rough and fine turns b. Turn outside diameter by external turning tool c. Drilling inside hole d. Turn inside hole(boring hole and fine turn) e. Turn pg7 thread f. Cutting, all steps are accomplished in one machining cycle.

*Actual height 13 of the side part to suit the glueing work of side part